TECHNICAL CAPABILITY

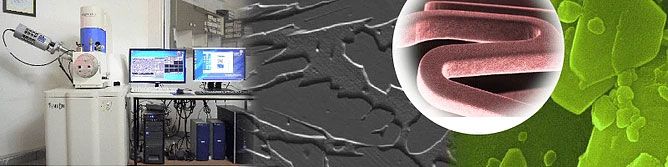

Metallography Tests at TCR

Macro-Examinations

In Macro-etching a specimen is etched and macro-structurally evaluated at low magnifications. It is a frequently used technique for evaluating steel products such as billets, bars, blooms and forgings. There are several procedures for rating a steel specimen by a graded series of photographs, showing the incidence of certain conditions and is applicable to carbon and low alloy steels. A number of different etching reagents may be used depending upon the type of examination. Steels react differently to etching reagents because of variations in chemical composition, the method of manufacturing, heat treatment, and many other variables.

Macro-Examinations are also performed on polished and etched cross-sections of welded material. During the examination, a number of features can be determined including the weld run sequence, which is vital for weld procedure qualifications tests. Apart from this, any defects on the sample are assessed for relevant specifications and compliance. Slag, porosity, lack of weld penetration, lack of sidewall fusion and poor weld profile are among the features observed in this type of examination. It is procedural to identify such defects, either by standard visual examination or at magnifications of up to 50X. It is also routine to photograph the section to provide a permanent record and this is known as a photomacrograph.

Macro-Examinations

This is performed on samples that are either cut to size or mounted on a resin mold. These samples are polished to a fine finish, typically a one-micron diamond paste and prior to an examination on the metallurgical microscope, it is usually etched in an appropriate chemical solution. Micro-examination is performed for a number of purposes, the most common of which is to assess the structure of the material. It is also customary to examine for metallurgical anomalies such as third phase precipitates, excessive grain growth, etc. Many routine tests such as phase counting or grain size determinations are performed in conjunction with micro-examinations.

Weld Examination

Metallographic weld evaluations take place in many forms. In its most simple format, weld deposits can be visually examined for large-scale defects such as porosity or lack of fusion defects. On a micro scale, the examination can take the form of phase balance assessments from weld cap, weld root or can even be checked for non-metallic or third phase precipitates. Examination of weld growth patterns is also used to determine the reasons for poor mechanical test results. For example, an extensive central columnar grain pattern can cause a plane of weakness, giving poor charpy results.

Case Depth

Case hardening may be defined as a process for hardening ferrous materials in such a manner that the surface layer (known as the case) is substantially harder than the remaining materials (known as the core). This process is controlled through carburizing, nitriding, carbonitriding, cyaniding, induction, and flame hardening. The chemical composition and mechanical properties are affected by these practices. The methodology utilized for determining case depth can either be chemical, mechanical or visual and the appropriate one is selected based on specific requirements.

Decarburization Measurement

This method is designed to detect changes in the microstructure, hardness or carbon content at the surface of steel sections due to carburization. To determine the depth, a uniform microstructure, hardness or carbon content of the specimen interior is observed. This method detects surface losses in the carbon content due to heating at elevated temperatures

Coating / Plating Evaluation (ASTM B487, ASTM B748)

A coating or plating application is used primarily for the protection of the substrate. Thickness is an important factor in the performance of the coating or plating. A portion of the specimen is cut, mounted transversely and is prepared in accordance with acceptable or suitable techniques. The thickness of the cross section is measured with an optical microscope. When the coating or plating is thinner than .00020, the measurement is taken with the scanning electron microscope. Cross-sectioned metallographic examinations of substrates with plating, surface evaluations, thickness measurements, weight per volume and even salt spray testing can aid in the evaluation of plating.

Surface Evaluation

The surface inspection includes the detection of surface flaws along with the measurement of surface roughness. One of the methods used to perform this test is the use of laser light. Measurement and analysis are possible when scattered light is reflected off the surface of a sample. An alternative method is the use of a motorized stylus (profilometer), where it is placed on the surface and the texture of the material is measured in micro-inches or millimeters.

Grain Size Determination

In order to establish a scale for grain size, ASTM E112 shows charts with outline grain structures for various dimensions. These universally accepted standards range from 1 (very coarse) to 10 (very fine). A material's grain size is important as it affects its mechanical properties. In most materials, a refined grain structure gives enhanced toughness, and alloying elements are deliberately added during the steel-making process to assist with grain refinement. Grain size is determined from a polished and etched sample, using optical microscopy at a magnification of 100X