CORE SERVICE OFFERINGS

Specialized Metallography Service

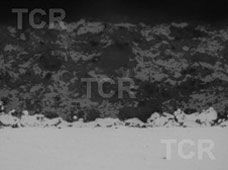

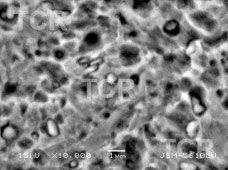

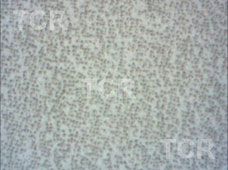

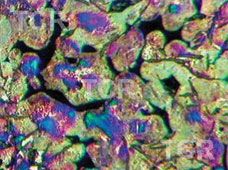

Specialized Metallography service

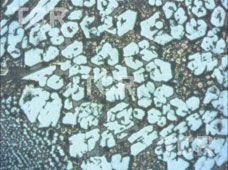

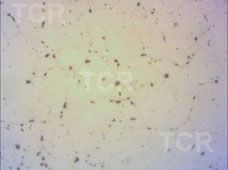

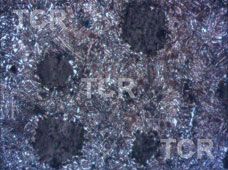

especially color metallography, is one of the strongest capabilities of TCR owing to its extensive research in this area of work. TCR has expertise in determining the various phases of the microstructure of material using color etching technique, which is commonly known as 'tint etching'. This etching has been used to color the phases present in many alloys such as cast irons, steels, stainless steels, nickel-base alloys, copper- base alloys, etc. for their phase identification. Color metallography is a useful method for characterizing microstructures of steel with multiple phases.However, the accuracy of this method depends on the metallographer's ability & skill to reveal the microstructural constituents of a specimen with sufficient contrast to allow rapid identification either by manual techniques or through the use of an automated Image Analyser. More than a science, color

metallography

is art for developing the microstructure that can distinguish the phases from each. TCR's team of metallographers are highly skilled to provide this service efficiently.TCR's metallurgists have vast experience in the interpretation of color metallographs and have developed specialized polishing and etching techniques that can develop a perfect contrast to enable a person to distinguish between the phases, precisely.