Corrosion Testing and Corrosion Studies

Corrosion Studies and Corrosion Testing

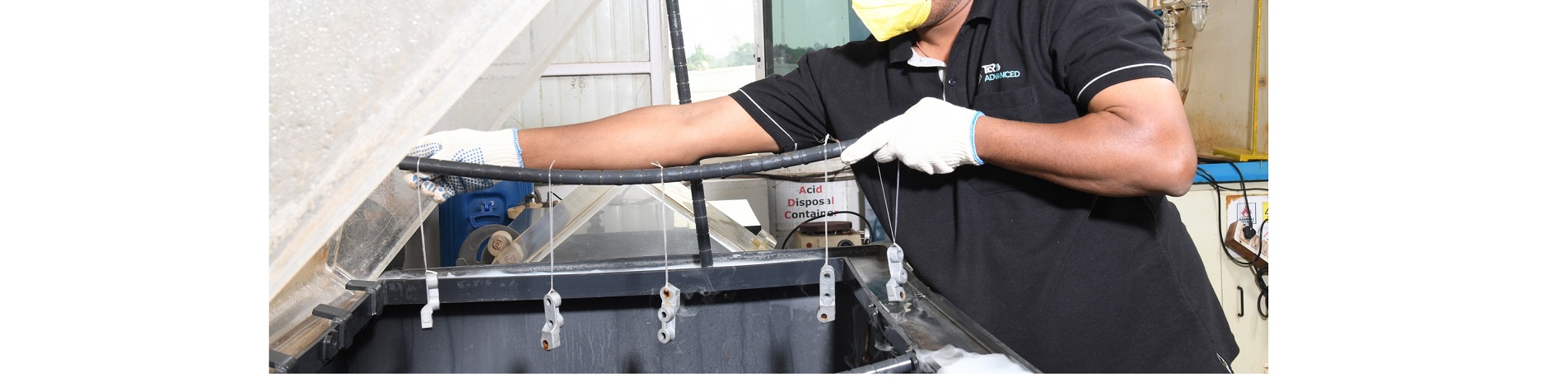

is undertaken by TCR Advanced as per ASTM, DIN, or as per individual client requirements. TCR Advanced has an in-house team of industry-specific experts to provide corrosion consulting, advisory services oncorrosion prevention

and corrosion control services including materials selection in a laboratory or on-site inspection.A wide variety of corrosion related tests is undertaken at TCR Advanced to determine the susceptibility to intergranular corrosion, pitting corrosion, stress corrosion cracking, etc. The range of instruments available to perform these tests is unrivaled in across geographies. TCR can also carry out testing under third party inspection agencies like LRS, TUV, DNV, ABS, BV among other inspection agencies.

TCR Advanced has added a fully automated avant-garde Salt spray testing facility. This test is extremely useful in analyzing the corrosion resistance properties of plating, coating, painted surfaces and materials that are used in corrosive environments.

TCR offers a comprehensive range of material testing services for corrosion problems that include:

Inter-granular Corrosion attack in Austenitic Stainless Steels

Oxalic Acid Etch test per ASTM A262 Practice A

Ferric Sulfate-Sulfuric Acid test per ASTM A262 Practice B

Huey Test, Nitric Acid test per ASTM A262 Practice C

Copper–Copper Sulfate–Sulfuric Acid test per ASTM A262 Practice E

Copper–Copper Sulfate–50% Sulfuric Acid test per ASTM A262 Practice F

Inter-granular Corrosion attack in Stainless Steels

Oxalic acid etch test per ASTM A763 method W

Ferric sulfate-sulfuric acid test per ASTM A763 method X

Copper-copper sulfate-50% sulfuric acid test per ASTM A763 method Y

Copper-copper sulfate-16% sulfuric acid test per ASTM A763 method Z

Inter-granular Corrosion of Ferritic, Austenitic & Ferritic-Austenitic (Duplex) Stainless Steel

Intergranular corrosion of stainless steels per ISO 3651 Method A, B, C

Metallic Materials

Potentiodynamic Anodic Polarization Measurement per ASTM G5

Immersion Corrosion Testing per ASTM G31

Stress Corrosion Cracking in Polythionic Acids per ASTM G35

Preparing, Cleaning and Evaluating Corrosion Test Specimens per ASTM G1

Examination and Evaluation of Pitting Corrosion per ASTM G46

Corrosion Rates and Related Information from Electrochemical Measurements (Tafel slopes) per ASTM G102

Corrosion Tests as per ONGC/EIL specification

Chloride Stress Corrosion Cracking in boiling Magnesium Chloride per ASTM G36

Chloride Stress Corrosion Cracking in boiling Calcium Chloride per ASTM G36

Determining Susceptibility to Stress-Corrosion Cracking of Aluminium Alloy Products

Stress Corrosion Cracking by Alternate Immersion Method per ASTM G44

Stress Corrosion Cracking of Aluminum Alloys per ASTM G47 Stress Corrosion Cracking Resistance of Al-Zn-Mg-Cu Alloys per ASTM G103

Exfoliation Corrosion Susceptibility of Aluminum Alloys (ASSET Test) per ASTM G66

Exfoliation Corrosion Susceptibility in Aluminium Alloys (EXCO Test) per ASTM G34

Intergranular Corrosion of Aluminum Alloys by Mass Loss (NAMLT Test) per ASTM G67

Intergranular Corrosion Resistance of Heat Treatable Aluminium Alloys per ASTM G110

Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys

Ferric Chloride pitting test G48 method A

Ferric Chloride crevice test ASTM G48 method B

Critical Pitting Temperature test for Nickel-base and Chromium-bearing Alloys per ASTM G48 Method C

Critical Crevice Temperature test for nickel-base and Chromium-bearing Alloys per ASTM G48 Method D

Critical Pitting Temperature test for Stainless Steel ASTM G48 method E

Critical Crevice Temperature test for Stainless Steel ASTM G48 method F

Detecting Detrimental Intermetallic Phase in Austenitic/Ferritic (Duplex) Stainless Steel

Sodium Hydroxide Etch test of Duplex Stainless Steel per ASTM A923 method A

Charpy Impact test for Classification of Structures of Duplex Stainless Steels per ASTM A923 method B

Ferric Chloride Corrosion test for Classification of Structures of Duplex Stainless Steels per ASTM A923 method C

NACE MR0175/ISO 15156: Petroleum and Natural Gas Industries- Materials for use in H2S-containing Environments in Oil and Gas production

Hydrogen Induced Cracking Test per NACE TM0284

Stress Oriented Hydrogen Induced Cracking Test (SOHIC) per NACE TM0103

Sulfide Stress Corrosion Cracking (Room Temperature) per NACE TM0177

Sulfide Stress Corrosion Cracking (90 Deg C, 16 bar) per NACE TM0177

Sulfide Stress Corrosion Cracking (120 Deg C, 20 bar) per NACE TM0177

Sulfide Stress Corrosion Cracking Double-Cantilever-Beam (DCB) Test per NACE TM0177 method D

Stress Corrosion Cracking (Four-Point Bend) of Materials for Oil and Gas Applications per NACE TM0316

Stress Corrosion Cracking (Four-Point Bend) per NACE TM0177 and ASTM G39

Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

Stress Corrosion Cracking (Ammonia Vapor Test) per ASTM B858

Detection of Cuprous Oxide (Hydrogen Embrittlement Susceptibility) in Copper per ASTM B577

Metallic Material and Coated Metallic Subtrate

Salt Spray (Fog) per ASTM B117

Neutral salt spray (NSS) per ISO 9227

Acetic acid salt spray (AASS) per ISO 9227

Copper-accelerated acetic acid salt spray (CASS) per ISO 9227