Technical Support for Indigenization & Import Substitution

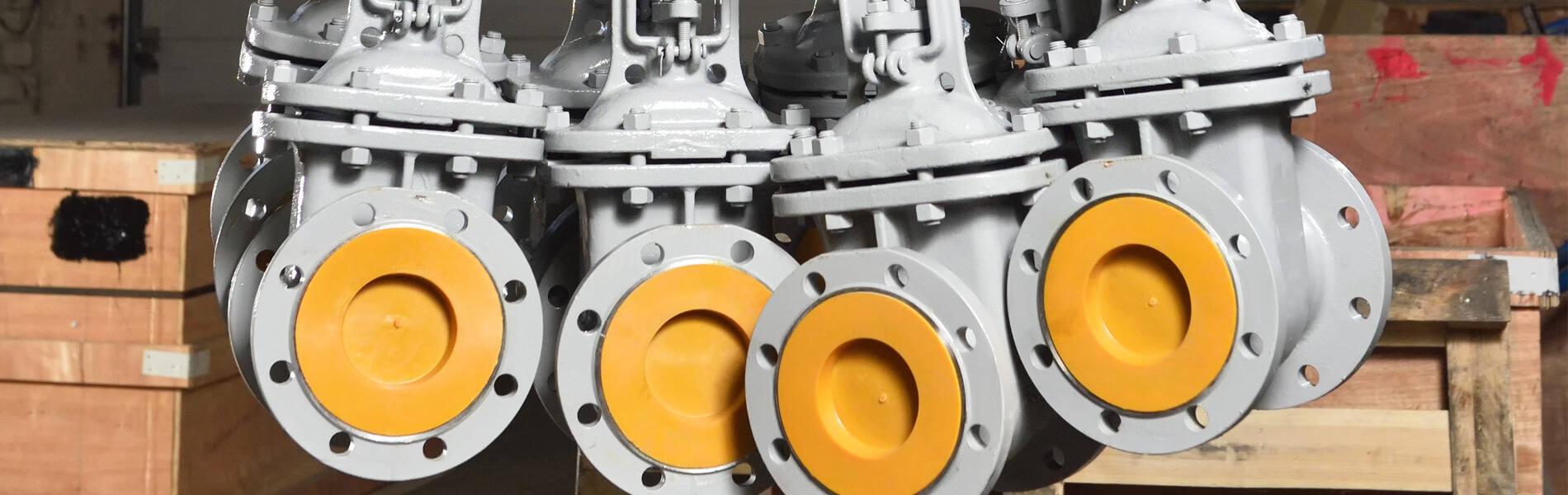

TCR Advanced has cutting edge equipment and extensive expertise to improve the quality of finished components in order to meet international standards & specifications. Our team of technical experts ensures safe and reliable functioning of components such as machine tools, dies, press parts, gears, shafts, axles, engine parts, parts for pumps and compressors, automobile parts, etc. for end applications in engineering, chemical, petrochemical, and fertilizer industries.

The goal is to unfold the metallurgical status/properties of imported components by destructive/nondestructive testing and to generate the baseline standard for indigenization. TCR's ISO 17025 certified material testing laboratory delivers best-in-class services consistently to customers around the world. Their deep industry knowledge ensures its performance and service quality are exemplary and they meet all the requirements, whether it is compliance, regulatory or client specific. TCR helps in augmenting the integrity and efficiency of equipment by creating a safe working condition for employees.